The story of Ruger's first centerfire pistol starts with the Colt M1911. One could even say that the Ruger pistols owe their existence to the Colt.

The Colt M1911 was adopted in 1911 and served with distinction through both World Wars, Korea and Vietnam, but by the late 1960's things started to go downhill and the U.S. Military Command was looking for a possible replacement.

In 1962 the U.S. Air Force switched back to a revolver, the Smith & Wesson Model 15 (38 Special) and the other branches were experiencing issues with cracked frames, poor quality replacement parts and then there was the issue of NATO compliance. All of the other NATO members had switched to the 9mm Parabellum as their standard side arm chambering, the U.S. was the only hold-out.

The U.S. Army, Navy, Air Force and Coast Guard agreed to commission a trial to find a new "Joint Service Pistol". Other U.S. Government "alphabet" agencies were also interested in the outcome of the trial.

The program was named "XM9" and had 85 requirements, 72 of which were mandatory. These included a 13 round minimum capacity in a detachable magazine, a double action/single action trigger and of course chambered in 9mm.

As soon as the program was announced, arms makers begin designing or modifying their pistols for the tests. It goes without saying (although I will state it anyway) that a government contract is highly coveted by arms makers. Beyond the revenue and increased production (which helps spread out fixed costs) there is the bragging rights and marketing that can help with civilian sales. Then there is of course the exports, the militaries of other countries were watching and could possible adopt the same pistol as the U.S. Military, saving time and money over hosting their own trials.

Over at Sturm, Ruger & Company, the plan was laid out to build a pistol that would meet the rigorous standards and be a solid competitor for the contract.

Bill Ruger himself gave the marching orders to Roy Melcher and Larry Larson. Roy would design the mechanicals and Larry would design the ergonomics. Ruger gave them no budget, they were free to spend what was needed to create the best, strongest, most affordable 9mm pistol ever.

While the design was being worked out in Southport, Connecticut Bill ordered the construction of a new factory in Prescott, Arizona.

He was spending his winters there and thought it would be a great place for a new factory for the pistol's production.

The basis of the design was the Browning High Power. A short recoil, locked breech pistol using the tilting barrel of the M1911. The pistol was dubbed the "P85", P for pistol and 85 for the year it was designed (or at least started).

The frame was made of aluminum, using Ruger's investment casting process. The internal parts were stainless steel and the slide was made of 4130 chrome-molybdenum alloy steel. The grips used a special plastic from GE called "Xenoy".

The frame mounted safety was also a de-cocker (another requirement from the gun trials). Ruger also made use of coil springs, something he favored in nearly all his guns.

Note the lanyard loop at the bottom of the grip frame

pictures courtesy of Bill Ruger & His Guns

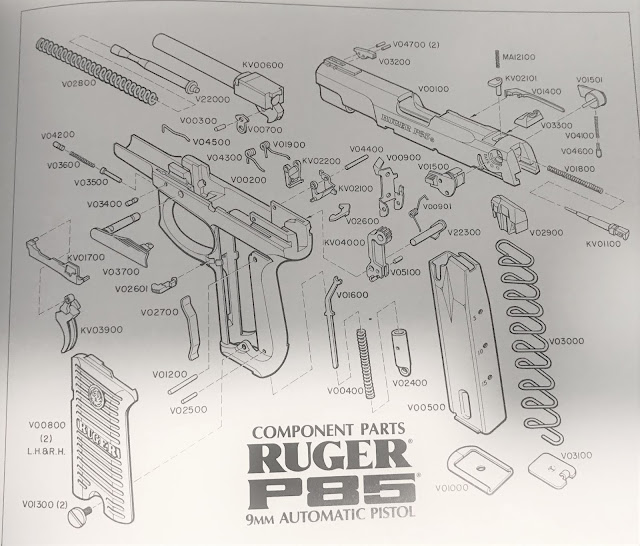

The P85 consists of 55 parts

Although Ruger was not able to get their pistol perfected in time for the initial trials, they did get a chance in 1987 when a second round of trials were announced. On August 17, 1988 Ruger submitted 30 pistols, 360 magazines and assorted spare parts for the retrial.

The Ruger passed every test given it by the testers, but in the end the decision makers decided to stick with the Beretta M9.

The P85 did get adopted by the Wisconsin State Patrol and the San Diego Police Department. Internationally it was adopted by the Turkish National Police and was ordered by governments around the globe including the Israeli Military.

When introduced in 1987, the gun had a retail price just under $300. That same year Glock 17s were selling for nearly $100 more. Ruger stuck with one of his founding principles he used to start the company 38 years earlier....give the customer a great product and an even better price.

Marketing materials hailed the pistol as "The Police and Military Semi-Automatic".

In 1990 the P85 was also offered in a Stainless version

The P85 was recalled due to an issue with the de-cocker. The revision was named the P85 MkII. When a P85 was repaired by Ruger the de-cocker was stamped "MKIIR"

The P85 MkII was replaced by the P89 in 1990.

Specs:

Action: Breech locked, short recoil semi-automatic

Chambering: 9mm Parabellum

Length: 7.75"

Weight: 38 oz

Barrel Length: 4.5"

Rifling: 6 grooves, RH, 1 in 10" twist

Mag Capacity: 15 rounds

Years Produced: 1987-1990

Number Produced: 700,000+ (includes the P85, P85MkII & P89)

The design lived on in other models including:

- P90 (45ACP)

- P91 (.40S&W)

- P93 (compact P89)

- P94 (P93 w/ longer barrel)

- P95 (P93 w/ polymer frame)

- P97 (P90 w/polymer frame)

- P345 (45 ACP, transition model)

Resources

Wikipedia - Ruger P series Pistols

Wikipedia Joint Service Small Arms Program

Shooting Times

Wilson, R.L. (2007), Ruger & His Guns, New York, NY: Chartwell Books, Inc.

No comments:

Post a Comment