Part 1

Part 2

When we left off we had prepped the stock for the oil finish, now we begin applying the oil. We will be using Minwax Antique Oil Finish. I don't know what is in it, but it acts much like tung oil.

The first coat goes on thick, rubbed in with my finger and then the palm of my hand, the wood will absorb the oil pretty quickly.

We remove the tape, but stay away from the checkering for now, if any oil does get into the checkering, dab it off with a paper towel. The checkering is oiled last.

After the first coat soaks in for 24 hours we begin filling the grain. We do this by applying plenty of oil and then wet sanding the stock with 400 grit sand paper. Remember only sand with the grain, not against it.

Then we wipe the slurry of sanding dust and oil into the grain, wipe with and against the grain, the slurry with fill the voids, making the stock smooth and reflect light evenly.

Here is the stock after the first sanded in coat is cured

This is the look we are after, we will sand in the next coat with 600 grit, then 1200 grit

Here it is after three sanded in applications of oil, we will sand it with 1200 grit and rub the oil in hard, then wipe with a special "lint-free" paper towel

note how the light reflects evenly but the surface is not super shiny, this was exactly the finish we are after

The last coat includes brushing oil into the checkering, when doing this you need to make sure the entire area is covered and there is no extra oil building up in the corners.

Time to start on the metal parts. We will be careful not to "over-restore" the gun, we want to mimic the finish the factory put on the gun back in 1947

After drifting out the sights I get to the sanding......the pitting was worse than I thought.....I don't know why I am surprised...it always is worse than I think

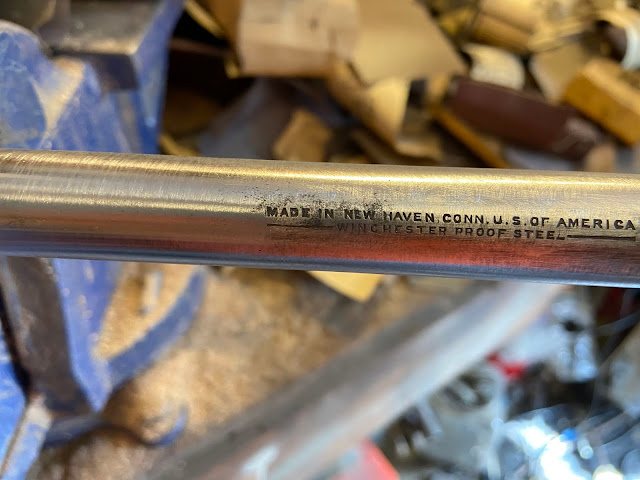

and of course I will have to work around the roll marks

After several hours, the barrel is ready, this is a 400 grit finish, before bluing I will give it a polishing with 600 grit paper and a light buffing with a Crocus cloth.

Next we get to work on the other small parts

I disassembled the bolt and will need to clean and polish some of the parts

I mimicked the original finish on the safety lever

The extractor was polished to a high shine from the factory, so after removing any blemishes, we polished it

The bolt handle will need some work

I removed the pitting from the ball knob and polished the bolt body, I will have to remove the bluing and polish it again after it comes out of the bluing tank

Then I removed the floor plate latch from the trigger guard, it was rusty and pitted as well

Trigger guard polished to a 400 grit finish, I was surprised at how much of the machine tool marks were still visible on the inside of the trigger guard

I removed the pits from the floor plate catch

The sight hood was pitted, I looked into buying a good used one, but they sell for $50 or more....so I spent an hour or so restoring its finish

I cleaned up the screws, again trying to mimic the original finish

One of the last steps was to bead blast the bolt handle and receiver. So I taped off the polished parts and bead blasted it with some special glass bead blasting media I bought just for doing Winchester and Remington rifles.

Stay Tuned.....

Hi TCB, I'm really enjoying your blog, thank you! Question on your process above, you mention sanding with oil and 400 grit only with the grain - is this back and forth or literally from recoil paid forwards direction?

ReplyDeleteYou then mention wiping the slurry with and against the grain - what do you use to do this with? Cloth or sandpaper?

Thank you.

Regards

David.

David,

DeleteYou ALWAYS sand with the grain, by the time you are ready to oil, you go ahead and removed the recoil pad. The wiping across the grain, forces the slurry of oil and sanding dust into the grain, filling it, which makes the wood smooth as glass.