I found a great deal on this ER-Shaw bull barrel at the gun show, it was 16", .920 diameter and was threaded.

The barrel had no finish on it, it would need to be blued, which is not a problem for me.

Here it is after a 600 grit polish

After bluing

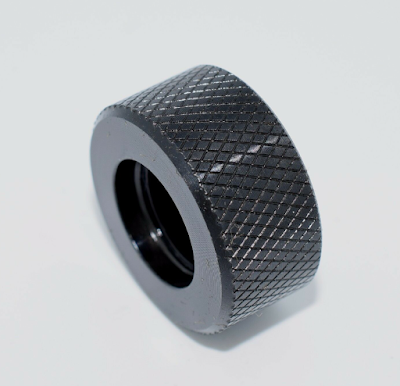

I purchased a thread protector for the barrel, I will eventually find a good flash hider for it.

For the receiver I will be using one of the parkerized Kingston Armory receivers that I bought a while back.

I also bought this bolt from JWH Custom

I also got one of their "target hammer" kits, which I combined with my typical action job in a stock plastic trigger housing that I purchased used for $30

A custom, oversized charging handle

I bought a UTG scope rail

Volquartsen supplied the take down screw

I used one of my custom made bolt buffers

I bought this 6-9" folding bipod

I purchased some factory trigger pins, V-block and screws

The scope and mount from my Marlin Night Prowler project will be repurposed for this project, it is a Bushnell 3-9 x 50mm with lighted mil-dot recital

For the stock I went with a Hogue Tactical Thumbhole over molded stock, they come in several colors, but I chose black....

Here is the gun after assembling all the parts. This 10/22 has very few Ruger factory parts on it, mostly in the trigger housing.

Costs for the project:

Kingston Armory steel receiver: $50.00

Trigger assembly: $30.00

JWH Custom target hammer kit: $19.99

JWH Custom scalloped bolt: $69.00

Generic charging handle: $14.99

Volquartsen take-down screw: $8.00

E.R. Shaw Bull Barrel: $40.00

Bull Barrel thread protector: $11.99

Hogue Target Thumb-Hole Stock: $90.48

Folding Bi-Pod: $13.96

UTG Scope Rail: $10.97

Bushnell 3-9 x 50mm Scope: $32.80

Scope mount: $13.73

Factory V-block and screws: $8.99

Factory Trigger Housing pins: $4.99

Total Investment: $419.89

**Update**

When I took the rifle out to dial in the scope, I was having failures to feed and extract. I thought it might be the receiver, as I had read that some of the Kingston Armory receivers had the barrel hole and magazine index hole drilled off-center. I decided to start with the smaller parts.

I swapped out the JWH bolt and charging handle/spring assembly with some factory units. The gun then functioned flawlessly and once the scope was dialed in showed itself to be very precise.

I am not going to place the blame for the issues with the JWH parts, sometimes parts from different manufacturers just don't play well with each other.

I have another project that I will use the JWH parts in and see how they do then.

On to the next project

Very cool!!

ReplyDelete