I cannot count how many times I have seen a shotgun for sale that was missing the front brass bead.

Often when shotguns are cut down the brass bead sight is not replaced. Sometimes the beads are lost or perhaps the person who cut the barrel didn't know what size thread & pitch the bead was threaded for. I am guilty of this as well....

Here is a chart showing the sizes used by the various shotgun makers.

Midway USA, Brownells and others sell some sizes of replacement beads, but finding the correct drill and tap size is another matter. It's too bad the makers did not standardize on one thread size.

I copied this idea from another home gunsmith (DIY_guy)who posts on the Firearmstalk forums. He made his own shotgun bead using a brass #4-40 screw. These are easy to find, as is the correct drill and tap.

The 4-40 screws were too small for the hole in my old shot gun though.

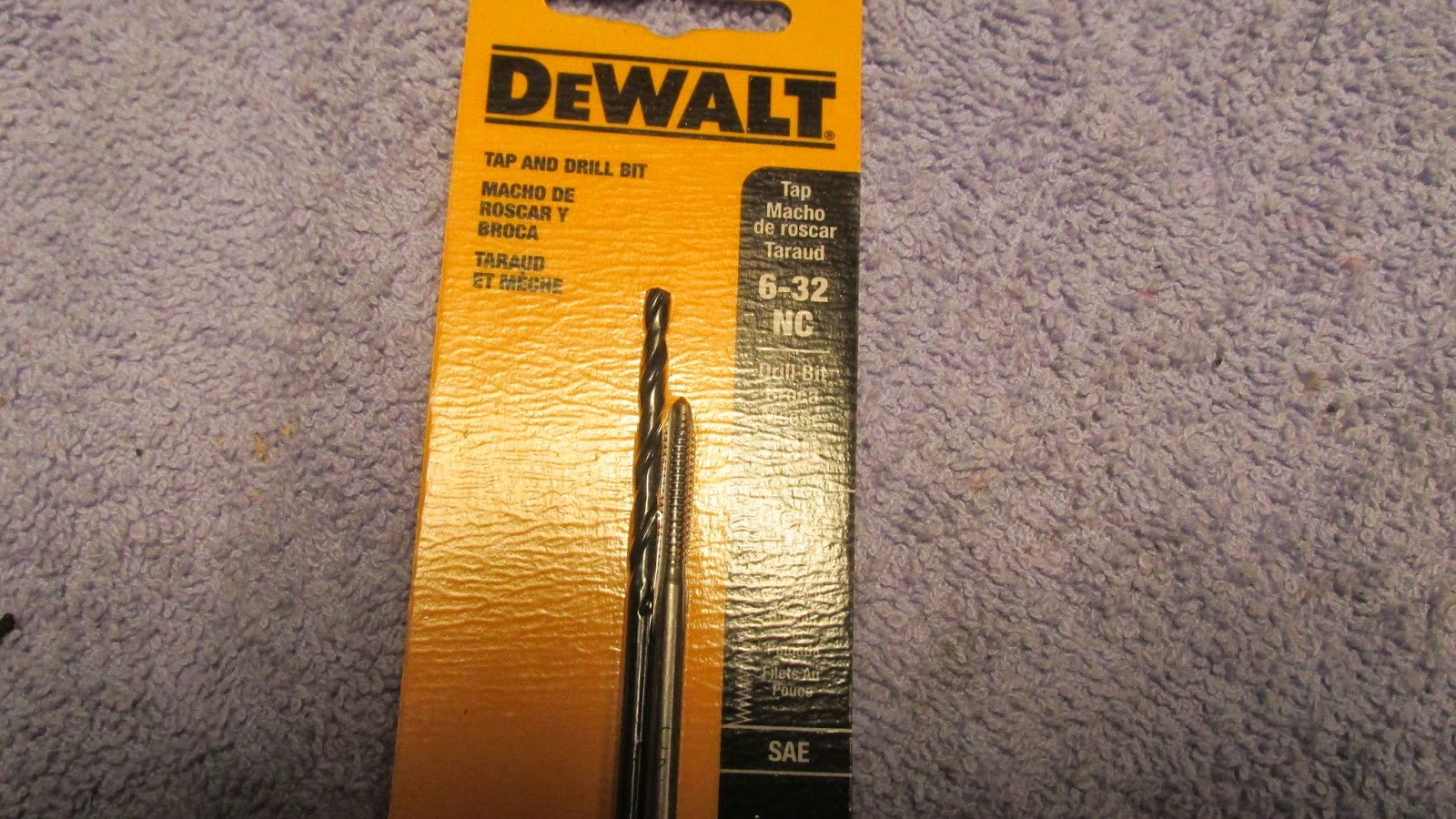

My Shotgun is of an unknown manufacturer. So I stepped up to the 6-32 screw. I was lucky enough to find some large thumb screws that had a large head, with plenty of material to shape into a round bead

They also had the drill and tap to properly prepare the hole for this screw

I chucked the screw into my drill and began filing it down to size using 100 grit emery cloth and a file

About 1/2 way there

I then chucked it into my bigger corded drill and mounted it in my vice so I could have both hands free to work the file and sandpaper

I then cut the threads short, I was a little nervous about the thread pitch, at 32 threads per inch, we will not have much holding the bead into the barrel

After a polishing on the buffer, I threaded it in, there is not much holding it in the barrel, so I don't think it will survive shooting. I'm not sure I like the round base or the height of it either....

I may have to look at other options. we'll consider this part one, to be continued...

References

Brownells

Looks good to me! How did it hold up?

ReplyDeleteIf it works .....

ReplyDelete